Diode Vs. CO2 Vs. Fiber Vs. UV Lasers – What’s the Difference?

How to choose your laser machine

When it comes to lasers, each type has its unique strengths and limitations, making them suitable for specific materials and tasks. Whether you’re a hobbyist, manufacturer, or DIY enthusiast, choosing the right laser can make a world of difference. Let’s break down the four main laser types—Diode, CO2, Fiber, and UV—to help you understand which one best fits your needs.

1. Diode Laser

What is a Diode Laser?

A diode laser uses diode-pumped solid-state (DPSS) technology, consisting of a diode pump source, a neodymium-doped crystal, and an optical resonator. Compact and efficient, diode lasers are perfect for portable, small-scale applications.

Pros of Diode Lasers:

Compact size and portability

Energy-efficient

High power density

Fast processing speeds

Long lifespan

Cons of Diode Lasers:

Limited material compatibility

Lower beam quality compared to CO2 lasers

Higher operating costs

Applications:

Engraving and marking metals, plastics, and ceramics

Cutting thin materials

Medical and cosmetic procedures

Research and development

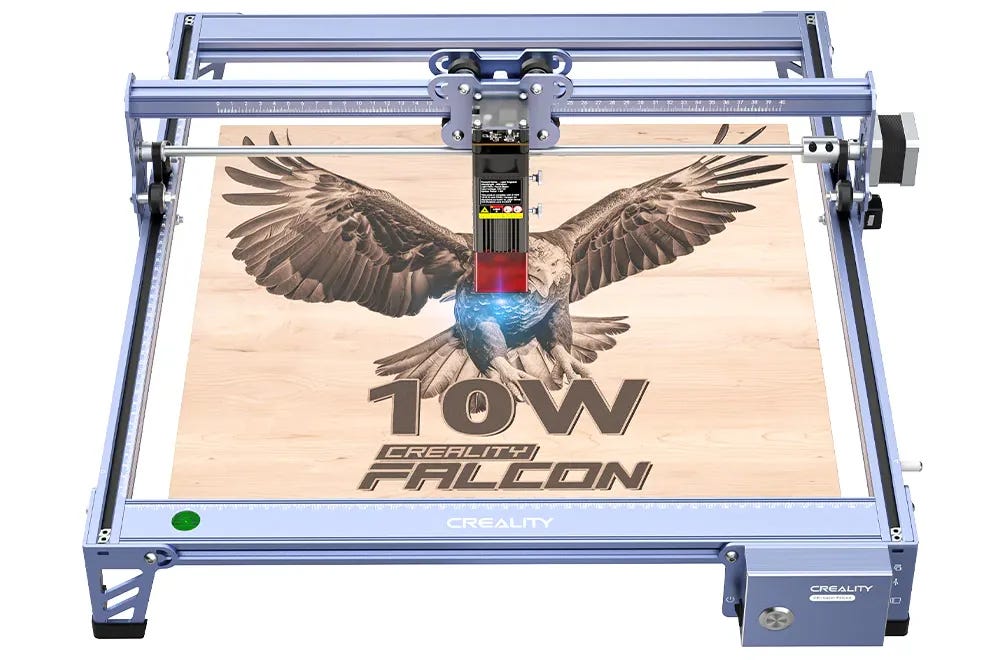

Real-World Example: Creality Falcon2 Diode Laser

The Creality Falcon2 is a great example of a powerful diode laser. It’s compact, user-friendly, and ideal for hobbyists who need precision engraving and thin material cutting at home or in small workshops.

FAQs:

Are diode lasers safe? Yes, they are safe when used with proper precautions, including eye protection.

Can diode lasers cut thick materials? No, they are better suited for thin materials. For thick materials, CO2 lasers are more effective.

2. CO2 Laser

What is a CO2 Laser?

CO2 lasers are the go-to choice for cutting and engraving organic materials like wood, glass, and acrylic. They use a gaseous medium excited by either direct current (DC) or radio frequency (RF) and emit a beam at 10,600 nm.

How Do They Work?

A CO2 laser focuses its beam onto a material, vaporizing the surface for cutting or engraving. RF-based CO2 lasers, like those found in high-quality machines, provide greater power stability and a longer lifespan.

Pros of CO2 Lasers:

Excellent for organic materials (wood, paper, glass, ceramics, rubber)

Good engraving speeds

Relatively low cost for entry-level systems

Cons of CO2 Lasers:

Shorter lifespan for DC systems

Not ideal for marking metals

Lower accuracy compared to UV or Fiber lasers

Applications:

Cutting acrylic, wood, and plastics

Marking glass and ceramics

Engraving organic materials

Real-World Example: OneLaser CO2 Laser Cutter

OneLaser’s CO2 laser cutter is a reliable solution for small businesses and hobbyists, offering precision for projects like wooden decor, glass engraving, and acrylic cutting.

3. Fiber Laser

What is a Fiber Laser?

Fiber lasers are the gold standard for marking and engraving metals. Operating at a 1,064 nm wavelength, they provide high-contrast, durable marks on hard materials.

How Do They Work?

Fiber lasers evaporate surface material through high-energy light, creating deep and precise engravings. With high efficiency and minimal power consumption, they’re widely used in industrial and commercial applications.

Types of Fiber Lasers:

Q-Switched: Budget-friendly but less flexible for fine-tuning.

MOPA: Highly versatile, allowing precise control over pulse width and frequency.

Pros of Fiber Lasers:

Highly versatile for marking metals

Fast engraving speeds

Long lifespan and low maintenance

Cons of Fiber Lasers:

More expensive than CO2 lasers

Limited effectiveness for organic materials (e.g., wood, glass)

Applications:

Metal marking (barcodes, QR codes, text)

Personalization (jewelry, switches, phones)

Industrial traceability

Real-World Example: xTool F1 Fiber Laser

The xTool F1 offers fast, accurate marking on metals and plastics. It’s a favorite among professionals for industrial-grade projects and customized products like metal keychains or engraved jewelry.

4. UV Laser

What is a UV Laser?

UV lasers are unique for their precision and ability to mark heat-sensitive materials. Operating at a shorter wavelength (355 nm), they use a non-thermal “cold process” to produce fine, detailed marks without damaging surrounding areas.

How Do They Work?

UV lasers break atomic bonds in the material without creating heat, making them ideal for delicate applications like glass etching or marking thin films.

Pros of UV Lasers:

Suitable for marking a wide range of materials (glass, plastics, metals, silicone, Teflon)

Ideal for precision and heat-sensitive applications

Low power requirements

Long lifespan and low maintenance

Cons of UV Lasers:

Not suitable for deep engraving or heavy cutting

Higher cost compared to CO2 lasers

Applications:

Marking glass, plastics, and precious metals

Electronics (PCBs, thin films)

Food and pharmaceutical packaging

Real-World Example: ComMarker Omni UV Laser

The ComMarker Omni UV Laser is a standout tool for intricate projects like glass engraving or fine plastic marking, offering exceptional precision with minimal heat damage.

Laser Type Comparison Table

Choosing the Right Laser

Each laser type shines in specific scenarios:

Diode Lasers: Perfect for portable projects and thin material marking. (e.g., Creality Falcon2)

CO2 Lasers: The top choice for cutting organic materials and acrylic. (e.g., OneLaser)

Fiber Lasers: Best for durable metal marking and industrial applications. (e.g., xTool F1)

UV Lasers: Ideal for delicate, precise marking on sensitive surfaces. (e.g., ComMarker Omni)

No matter your needs, understanding these laser types helps you make an informed decision. If you’re unsure, reach out to our team for tailored recommendations to fit your project!